Industrial Location:

Location is no doubt a relative concept. It refers to something in relation to other things. Thus, industrial location refers not just to the spatial distribution of industry, but also to relations between that distribution and other phenomena. As M. A. Weber has noted: “Industrial location theory explains the spatial distribution of industry by referring to other aspects of society.”

Location and Production Costs:

Most theories about location stress the significance of production costs in firms’ choices of places to operate. It is generally believed that firms tend to locate in those places that will yield the lowest possible production costs. Some do this by locating their facilities near their customers, others do this by being near inputs such as labour and raw materials used in their production processes.

Locations near Inputs:

Some firms locate near their inputs because the inputs are perishable and so must undergo rapid processing if the firm’s costs are to be kept at a minimum. For example, dairy product producers locate near cattle farms, and fish canneries near fishing ports.

ADVERTISEMENTS:

Wineries tend to be located near the grape farms rather than near connoisseurs of wines. Other firms locate near supplies of the particular types of labour their processes require. So locations with relatively inexpensive labour, are prime sites for firms needing workers who will work at low wages.

Firms using inputs that lose weight and bulk during the production process also tend to locate near their inputs, to minimize their transportation costs. For instance, cement plants are located near places of limestone deposits. The idea of transportation costs as a major determinant of location of firms was presented long ago by Alfred Weber.

The simplest, and historically the earliest, theory of industrial location is the minimum cost theory, first published in 1909 by Alfred Weber. The major part of Weber’s theory examines the location of a factory-firm or of a single new factory belonging to a corporation.

In general, a firm seeks to make profit- maximizing decisions: that is, it tries to collect the correct (in terms of its costs and benefits) amount of information in order to choose that location among those examined for which profits are greatest.

ADVERTISEMENTS:

A factory buys raw materials and semi-processed products, organizes a labour force and machinery to make the product, and deliver that product to warehouses. Thus, the costs that the factory has to incur are the costs of raw materials and semi-finished goods; the costs of plant and equipment and processing in the factory; and the costs of delivering the finished product to the buyer (warehouse).

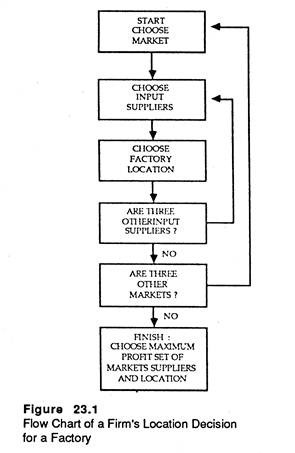

The location decision thus has several components. The firm has to decide on the markets which the factory is to serve (and its output levels), select suppliers of inputs, and then must choose a location for its factory.

The theoretical analysis of these decisions proceeds in the way shown in Figure 23.1. First, the firm must decide on an appropriate market and on the amount that it will try to sell in that market. Next, it must decide whether sellers of inputs are to be patronized. Given these two decisions, the firm must then find the maximum profit location.

Weber cited the example of a steel firm whose major customers are a thousand miles from the coal and iron ore mines that will provide these inputs for its production processes.

ADVERTISEMENTS:

Assuming five tonnes of coal and iron ore are needed to produce one tonne of finished steel, producing at the customers’ location would require this firm to ship 500 tonnes of inputs one thousand miles for each 100 tonnes of steel.

On the contrary, if it locates its production facilities at the site of these raw materials, it could use them to produce for the same customers and have to transport only the 100 tonnes of steel.

Locations and Customers:

Firms with products that are more fragile or perishable than the inputs required to produce them tend to locate near their customers to reduce breakage and spoilage costs.

Because bread spoils in a few days’ time while wheat can last months and years, bread is not produced near the wheat farms that provide its principal ingredient, and then transported around the country. Rather, the wheat is sent to bakeries, located in cities, where the bread customers live.

Similarly, market-oriented production occurs when products or services cannot be transported. For example, fresh pizza, religious salvation, police protection, and haircuts produced in Calcutta cannot be transported at any cost to Shimla or wherever the people are who want them. Instead, the public and private firms producing such goods and services must locate near their customers.

Firms producing goods and services that increase in weight or bulk during the production process also tend to locate near their customers in order to minimize transportation cost. For example, automobile assembly plants are usually located near their customers since the parts required for many cars can be shipped in the same space required for one completed automobile.

Likewise, products such as Coca Cola that increase in weight tend to be produced near their customers; its costs less to transport a few cans of syrup to which water (a universally available input) can be added at the customers’ location, than it would to add the water at the syrup factory and ship great masses of bottles and cans of Coca Cola across the country.

The Market Areas of Firms:

Firms in locations scattered around a country tend to provide goods and services for customers within specific geographic regions. These are the firms’ market areas. Then the pertinent question is how far from its production site can a firm sell, before it cannot compete for customers.

ADVERTISEMENTS:

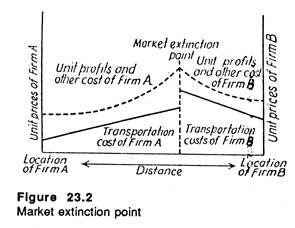

The basic answer is that a firm can sell wherever its prices can be equal to or lower than those of its competitors. The market area of each firm tends to extend in each direction from its location as long as its costs and the profits required by its techno structure, and thus its prices, can be lower than those of other sites. Such a situation is shown in Figure 23.2.

It represents the basic relationship between firms and their market areas, for firms having different locations, production costs, and transportation costs. Specifically, it shows that the prices the firms will charge rise as customers are farther and farther away from each firm’s production site. This tends to give each of the firms a location monopoly for the customers located near its production site.

Other firms could attempt to sell to such customers, of course, but their prices would have to be higher to cover their higher costs. Moreover, at some distance from its production site a firm’s costs tends to rise so much that it loses its price advantage. This is the market extinction point, the outer edge of its market. Beyond this point customers can buy at lower prices from other firms.