In this article we will discuss about the development of capitalist enterprise during different periods in India.

Development of Capitalist Enterprise during 1857-1914:

Up to the 1840’s, the major economic and commercial developments in India centered upon the growth of mainly British private enterprise in Banking, insurance, indigo-plantations, steamships, cotton presses, early tea-plantations and coalmines-activities which were geared almost exclusively to the growing external trade with Britain.

The period, beginning with the decade 1850—1860 and ending with the First World War, saw an extended involvement of British Capital and enterprise in these activities. There was also a simultaneous growth of jute and cotton manufactures, state-initiated railways, expansion and associated-growth of foundries and metallurgical industry, significant expansion of coalmining and tea-plantations.

It was in 1853 that a short line of railway was extended from Bombay and in the next year a short line was opened from Howrah to the Raniganj coal-fields. This furnished a cheap supply of fuel for the Calcutta area—an advantage which Bombay never enjoyed.

ADVERTISEMENTS:

Another short line was opened out of Madras in 1856. Construction was started on the first jute mill in 1854 and the first cotton mill was also put into operation at Bombay in the same year.

Apart from these factory industries, the period also saw the beginning of the use of modern methods in the mining of coal. From these beginnings, India started her belated journey towards the development of large-scale capitalist enterprise.

Other cotton mills were opened in the neighbourhood of Bombay, chiefly by Parsecs, and jute mills in the vicinity of Calcutta where Europeans were active. By 1865, there were 13 cotton mills in the Bombay Presidency although the progress of the jute industry was rather slow, only one mill having been added between 1854 to 1863-64.

The year 1865 is also important because the first cotton mill in Kanpur was registered in this year and the city was linked with Calcutta by the East Indian Railway.

ADVERTISEMENTS:

The blockade of the southern ports in the American Civil War had shut off Lancashire’s supply of raw cotton and the resultant high prices in India brought in large amounts of liquid capital and stimulated all sorts of financial and industrial activity. However, the slump which followed put a stop to growth during the later half of the decade. As a result, no new cotton mill was started in Bombay presidency until 1870.

After 1875, I here was a veritable boom when several up-country mills were established. Besides growth at Ahmedabad and Kanpur, there was also the beginning of the later greatness of Sholapur and Nagpur. Jute manufacture also experienced a similar upswing so that by 1878, the number of jute mills increased to 18.

The wide-spread famine of 1876-78 brought a brief lull in both cotton and jute industries but soon another boom set in before 1885 which “marked a turning point in the upward climb of the cotton mill industry.” The jute manufacturing capacity, however, continued to grow less rapidly.

The growth from 1890 until the 1 World War was fairly steady in all fields except that the period 1895—1900, marked as it was by two great famines and the Plague epidemic, saw a considerable check on the progress of the cotton industry. The depression lifted by about 1905 and thereafter, there was a rapid advance in all industries.

ADVERTISEMENTS:

The process of industrialisation was helped, in particular, by the Swadeshi Movement which stood for the encouragement of the use of India-made manufacturers and the non- purchase, rejection, or even boycott of foreign goods.

Though the Swadeshi Movement made its mark in the course of the All India Agitation against the partition of Bengal, the ground for the instantaneous and wide acceptance of the ‘Swadeshi idea’ and for the dramatic success of the movement had been prepared earlier. Between 1880—95, the tide of Swadeshi had been steadily rising throughout the country.

Popular songs against l he destruction of indigenous industries and the use of English machine-made goods found easy currency among the people of western India. The movement was intensified in 1896 when the country burst out in anger against the imposition of countervailing excise duty on Indian Cloth. Its formal launching spread a great wave of industrial enthusiasm in the country.

The number of registered joint-stock companies rose from 1340 in 1900 to 2744 at the outbreak of the I World War and their paid-up capital increased from rupees 34.7 crores to rupees 76.6 crores. A number of factories for the manufacture of piece-goods, soap, matches, pencils and cutlery, and stores where the products of these factories could be sold, were started.

By 1913-14, the number of cotton mills alone increased to 246 employing 2.60 lakh persons; of jute mills to 64 employing 2.16 Lakh persons; coal production stood at 16.4 million tons and coal mining provided employment to 1.51 lakh persons. Tea exports expanded to 289.4 million lbs. in 1913—14.

Thus, on the eve of the 1 World War, continued endeavour by British and indigenous capital and enterprise had somewhat expanded India’s otherwise narrow industrial base. But its impact on the over-all economic growth of the country did not put India into the ranks of industrialised countries.

The industrial pattern was largely based on coal mining, cotton and jute textiles, railways and allied workshops, some foundries and metallurgical plants, and ordinance factories.

There was also an impressive growth of tea plantations, shipping and dockyards, insurance and banking facilities. One crowning achievement of the period was the founding of the Tata Iron and Steel Company in 1907 and the commencement of its operations in 1912.

Other miscellaneous industries such as cotton gins and presses, jute presses, paper mills, rice mills, sugar factories, petroleum refineries, leather workshops, engineering workshops had also come into existence but they were not of sufficient magnitude and importance.

ADVERTISEMENTS:

As the Industrial Commission’ pointed out, “there were wide blanks in our industrial catalogue.” Basic and heavy industries such as machine tools, electrical equipment, and chemicals were conspicuous by their absence.

The country was still dependent for most of its manufactured goods including Consumer goods, on imports from England which exceeded the combined imports of Australia, Canada, and South Africa.

Even what little development had been obtained was at the cost of the country’s old cottage industries. Village Industry, as a whole, had decayed and, in the towns, the majority of the old handicrafts had declined, while some of the more important crafts became stagnant.

In certain respects, however, the period was qualitatively different from the one ending towards 1850. Import substitution movement in cotton textiles from the 1850’s and more noticeably in steel at the turn of the century, marked a significant shift in investments which, until then, had been almost exclusively geared to external trade.

ADVERTISEMENTS:

Another striking development was that indigenous enterprise, centered in Bombay Presidency, now led the way whereas earlier the British capital and enterprise alone had initiated activity in nearly all the significant sectors such as Indigo and tea-plantations.

Apart from the “Schumpeterian innovative role” of Indigenous enterprise in cotton textiles and steelmaking, indigenous enterprise flourished on a large scale during this period, entering new fields and extending its commercial and trading interest further.

Indeed, as Industrialisation proceeded at its slow pace through the 19th century, British and indigenous enterprise came to inter-penetrate many common fields. Indian enterprise followed into coal mining, tea, and jute manufactures. British agency houses, in turn, entered the cotton textile industry.

However, the relations between the British and indigenous entrepreneurs were not as between equals but reflected the colonial pattern. The overall pace of industrial growth was slow. Between 1880-1914, large-scale industrial output, as a whole, increased at an average annual rate of between 4-5% as compared with 6% in Sweden and Russia and 7% in contemporary Japan.

ADVERTISEMENTS:

In order to understand the causes of this slow growth, one point may be borne in mind. Since the Indian farmers had only a small surplus, a large industrial growth required either an agricultural change yielding a larger surplus, or development of a large-scale export of manufactures.

For exports to have made a substantial contribution to India’s economy, a large trade drive based, to a considerable extent, on successful iron and steel and engineering industries was needed.

Any effort along any of these lines-major agricultural change or a successful trade drive, was nowhere in sight, ln-fact, in the course of establishing her railway net-work, India herself had generated a very large demand for iron and steel products.

Had the govt., abandoned its laissez-Faire policy and helped India develop iron and steel and the industries linked there with, especially coal mining and engineering, from say 1860, India would, by 1941, have been one of the largest industrial producers in the world.

As it was, despite the undoubted growth and diversification of enterprise and industrial investment in the 19th century, and the indisputable prosperity of centres as Bombay and Calcutta, the overall impact on the Indian economy was not anything more than ‘perfunctory’.

Capitalist Enterprise during the First World War:

The First World War highlighted the inadequacy of India’s industrial base. It brought home to the British government not only India’s key role in Imperial defence but also the limitations of her contribution to the war effort in the absence of significantly greater industrial expansion.

ADVERTISEMENTS:

The war led to an immediate stoppage of supplies from the enemy countries like Germany, England and her allies, being themselves busy with the war, were unable to supply Indian needs. Imports were confined to only the most essential goods on account of acute scarcity of shipping, difficulty of finance, and the menace of enemy submarines on the high seas.

Simultaneously, there grew a vast demand for Indian goods in order to supply the requirements of Allied armies. An exceptional opportunity was thus presented for the ‘Swadeshi industries’.

The effect of Bombay industries was almost entirely advantageous. The cotton mills, gins and presses were exceptionally prosperous. In Bengal, the main effect was to increase industrial activity in general and to stimulate the jute industry and coal mining in particular. The number of cotton spinning and weaving mills rose to 277 and that of jute mills to 76.

In Madras, the tanning of leather, soap, fishtining, and ship-building industries were all stimulated. Considerable encouragement was also given to the manufacture of chemicals, mineral acids, oils, paper, glass, cement, cutlery, paints and varnishes, and surgical instruments.

The number of joint-stock companies registered in the country increased from 2552 to 2789 and their capital grew from rupees 72.10 crores to rupees 106.61 crores.

The outstanding achievement of the period was the secure establishment of the most important metallurgical industry—The iron and steel. Steel production increased from 19000 tons in 1913 to 1,24,000 tons in 1918. The production of chromite and wolfram received a sudden impetus. Salt petre also revived, even though, temporarily.

ADVERTISEMENTS:

The First World War marked a major ‘structural break’ as for as composition of private investment in modern manufacturing industry is concerned. From now onwards, the level of investment in the cotton mill industry began to grow more rapidly than the level of investment in the jute mill industry. Correspondingly, the level of investment in Western India rose relatively to that in Eastern India.

The War meant to the agricultural producer a loss of his old export markets. However, to the manufacturer, it meant the stoppage of foreign competition in cotton and coal or the creation of large special demand as in jute, manganese, and other minerals useful for munition purposes.

The price of manufactured goods rose while the rise in the price of raw-materials was comparatively slight and wages rose little, if at all. Further, the difficulties of importing machinery and other stores strengthened the position of existing producers.

In the absence of state regulation of prices, industrial manufacturers made abnormal profits, especially during the war years. Between 1915—1922, cotton mills paid an average dividend of 53% while the gain to the shareholders of jute mills was 90% per annum between 1915—1924. Instead of setting them part for future replacements and development, producers mostly frittered them away in dividends.

Another notable event of the period was the change in the attitude of the government towards industry. Before the war, the attitude of the government was one of absolute Laissez-Faire so that all “—attempts to encourage Indian industry by means of pioneer factories and govt, subsidies were effectively discouraged from Whitehall.”

Tariff policy was largely governed by the wishes of English manufacturers. The War changed all this. It brought out in a striking manner the industrial poverty of India and made the government realise the extent of India’s dependence, for plant and machinery, on imports from abroad.

ADVERTISEMENTS:

The need for munitions was specially pressing and, in February 1917, a Munitions Board was set up “to control and develop Indian resources with special reference to the needs created by the war, to limit and co-ordinate demands for articles not manufactured or produced in India, and apply the manufacturing resources of India to war purposes with the special object of reducing demands on shipping.”

The primary object of the Board was to meet the demands of the armies operating in Mesopotamia but it helped in the development of Indian Industries by purchasing in India articles and materials needed for civil and military departments, by diverting orders from the U.K. to manufacturers in India, by assisting in the import of plant and technical or chemical experts from abroad, and by giving expert advice and direct and indirect encouragement to those prepared to establish industries in India.

In addition to purchasing large quantities of jute manufactures, cotton and woolen textiles, leather-goods, tea, mica, wolfram, timber, salt petre and a host of other commodities, the Board paid special attention to the encouragement of key industries.

Some of the accessories used by the milling industries in India such as roller-skins, pickers, sheep-skins for rice polishing, Belting etc., began to made in India. Other industries to which considerable attention was paid were the manufacture of anti-friction metal, ferromanganese, glass, pottery, refractory bricks, disinfecting-fluids, glucose, coir articles.

During the 18 months from 1 April, 1917 to the end of September 1918, the Board spent rupees 34 crores on the purchase of goods in India.

India was, however, unable to take full advantage of the temporary protection provided by the war due to the scarcity or total absence of technical exports, shortage of skilled labour, of railway wagons, coasting vessels, coal and coking plant.

ADVERTISEMENTS:

As a result, Japan and America stepped in to fill the gap created by the shortage of supplies from the U.K. Their share in the import trade increased from 2.5% and 3.1% in the pre-war period to 10.4% and 7% respectively.

The overall scene at the end of the war was far from encouraging. As the Fiscal Commission (1921) noted, “industrial development in India has been moving slowly compared with other countries, its population or its natural wealth.” What is more, the industrial structure was unbalanced.

Not to speak of such deficiencies as machine tools, steam-engines, boilers and gas engines, hydraulic presses and heavy cranes, India did not have machines to make nails or screws, simple agricultural tools such as ploughs, spades, showels, pick-axes or hand tools used in the cottage industries such as reeds, shuttles, and pickers.

We may conclude with P.S. Lokahathan that the First World War, “beyond affording temporary gains to a few established industries, did nothing to set the country firmly on the road to industrialisation.”

Development of Capitalist Enterprise during the Inter-War Period:

The end of the war was followed everywhere by a short-lived boom and hectic industrial activity caused by the expectation of strong revival in demand, high level of war-time profits, and inflation of currency. In India, this was a period of great prosperity for the manufacturing and export industries such as cotton, jute, cement, Iron and Steel, manganese, oil seeds, hides and skins etc.

The dividends paid by the Bombay Cotton Mills were 23.7% of the paid-up Capital in 1918, 40.1% in 1919, 35.2%in 1920 and 30.1% in 1921. On account of the hysteria and frenzy to make big fortunes in a week or a fortnight, numerous new companies, for every conceivable object, rose like mushrooms.

This may be seen from the fact that in 1918—19, the number of registered companies stood at 2789 with a paid-up capital of rupees 106.6 crores; in 1921—22, their number had risen to 5189 and paid-up capital to rupees 230.5 crores.

The boom, as was to be expected, was short-lived. The tide turned about the middle of 1920 and a prolonged period of depression set in. According to Samant and Mulky, between 1919—1928, as many as 4000 companies failed and the outlook for those which survived was far from bright.

The subsequent rise in the exchange value of the rupee from 1924 further prolonged the depression and intensified the force of competition at a time when the depreciated currencies abroad had placed India’s competitors at an advantage.

On such a situation was superimposed the world depression which brought about a further fall in prices. India, being an agricultural country, suffered more than industrial countries like Great Britain.

India’s exports declined from rupees 339 crores to rupees 135 crores so that the payment of ‘Home Charges’ and debt-interest had to be met by the export of ‘distress gold’. This meant impoverishment of the Indian market and its depression.

From 1927, the predominant characteristic of the Indian tariff system was ‘Imperial Preference’ which gave the British products an advantage over both non-empire and Indian products in the Indian market.

It transformed the policy of ‘Discriminating protection’ into what Kate Mitchell likes to describe as a “system which assisted British industry to compete in the Indian market while giving India, in return, the privilege of favoured rates for the sale of her raw-materials and semi-manufactures in the British market-an obvious attempt to revert to the pre-war status.”

In-spite of these limitations, there was considerable industrial development in the country. Within a decade after the war, factory industry had expanded and diversified into minerals and metals, food, drink, and tobacco, chemicals and dyes, paper and printing, processes relating to wood, stone, glass, hides and skins, and other miscellaneous activities.

By about the beginning of the second world war, the Indian industrial structure supported a considerable production of cement, paper, cotton piece-goods, sugar, pig iron and steel ingots while industries such as cycles and textile machinery had already emerged.

The diversification and expansion of industries during the inter-war period was, for once, encouraged by a tariff policy which broke with the tradition of free trade. The appointment, in October 1921, of the fiscal Commission, which reported in favour of discriminating. Protection, is one of the land-marks of Indian industrialisation.

During 1923—39, the Tariff Boards made numerous enquiries resulting in varying degrees of protection to the Iron and Steel, cotton textiles, sugar, paper, and gold- thread industries. In industries such as Iron and Steel, tariff protection was invaluable in getting over the depression following the vast expansion during the First World War.

It would have certainly suffered a severe setback or perhaps bankruptcy if protection had not been granted to bale it out of the expensive and considerable expansion on one side and the difficulties created by continental dumping on the international market on the other.

During the seventeen years, 1922—1939, of protection, the production of steel ingots expanded 8 fold; of cotton piece-goods by times; of matches by 38%, paper by 18%, and sugarcane recorded a tremendous 35 times increase from 24000 tons in 1922 to 931000 tons in 1938.

As can be seen, the maximum growth rate was achieved by sugar and steel industries, both having a small base in the preproduction period. The jute industry, on the other hand, was the only substantial export industry that suffered from a failure of world demand during the depression.

A relatively small rate of growth of cotton industry was due to the fact that it had a big base and protection went mainly to offset the effects of dumping and currency depreciation.

Region wise, the most rapid progress was made in U.P. which included the sugar industry while Bengal came very low because her two main industries—jute and coal, had both developed before 1925, then suffered from depression and could not be stimulated by protection.

The period also witnessed a relative decline in the importance of Bombay City’s cotton mill industry. It was indicative of the general change which was proceeding in the location of India’s industries. There was a shift away from the big cities where higher local rates, taxes and rents together with serious labour problems unduly raised costs.

Industries tended to shift towards Indian states where factory and labour laws were less strict. Between 1921—39,on nearly 33% of the total industrial expansion, measured in terms of factory employment, look place in the States, particularly Hyderabad, Mysore, Baroda, Kashmir and Central Indian States.

Although indigenous enterprise had managed to get a much larger share of modern industry than it held before 1914, foreign capitalists were still firmly in control in the staple industries. In fact, there was already a shadow of the shape of things to come in the penetration of Indian industry by large foreign firms controlled from abroad.

Unilever, I.C.I., Dunlop, General Motors, and others established their branches or subsidiaries in India. Thus, even before Indian capitalists had wrested control over the economy from the pre-capitalist elements and from the old European firms, they had to suffer the invasion of new fields of industry by international cartels.

One noteworthy feature of the development of capitalist enterprise during this period was the increasing concentration of production as well as capital. In this context, the rapid increase in the number of various Chambers of Commerce and industry, associations, community organisations is significant.

With the help of these trade organisations, big businessmen found it easier to conclude various deals and come to terms on joint operations. In Bombay, the high degree of concentration of production and capital in the thirties brought into focus the question of uniting the textile mills into a large trust to curtail production by mutual agreement.

In 1934, an Association of Indian Soap Factory Owners was formed “to protect the common interests of the capitalists in the industry, render technical aid, lobby for protective tariff, help start workshops for the manufacture of mechanical equipment and wherever possible, to arrange joint- purchase of materials. In other words, this form of unified action revealed individual features of the simplest forms of monopoly agreement. This new feature of the development of big indigenous capitalist enterprises was particularly obvious in the evolution of the sugar industry in which a tendency towards monopolistic consolidation became evident very early. Although, the first serious attempt was made in 1934, the All India Sugar Syndicate was established in July 1937 with a membership of 92 sugar factories holding about 60% of the unsold stocks r sugar in the Country.”

Another industry which developed rapidly after the First World War was cement.

In 1914, the amount of cement produced was 945 tons; by 1925, the cement plants already in existence united in an association of the Cartel type which made it possible to raise profits and wage a compaign for lower railway freight rates. By 1930, the cement marketing Company of India controlled the output of nearly all the factories on a quota-basis.

The combined potential output was 1 million tons but the factories were not allowed to work for more than 60% capacity. The process of monopolisation did not end here. Early in 1936, British and Indian cement Plant owners, at the initiative of Mr. Dinshaw, joined to form a united cement Trust—the Associated cement Companies of India. This was the old European story in which Cartel was turned into Syndicate and syndicate into trust.

To sum up, during the inter-war period, which saw the triumph of socialist industrialisation in Russia undoubtedly a measure of advance took place in India also. The production of cotton piece-goods, paper and steel recorded impressive improvement.

In the case of sugar, India became self-sufficient within a period of 4 years, 1932—36. The cement industry produced 95% of the total requirements by 1935—36. Other industries like matches, glass, Vanaspati, Soap, and a number of engineering industries also witnessed increased production.

A beginning in the manufacture of electrical equipment and goods was also made by 1938—39. There was a tendency for gradual displacement of imported consumer goods by local production. Jute and Plantation industries were also in a position to export substantially greater quantities to foreign markets.

Decisive, however, for industrialisation is not the development of consumer industries like textiles or sugar. In the words of Knowles “the real change comes in any country when the iron and steel industries begin to be successful—the development of metallurgical industries means the real industrial revolution.” And it is here that the real weakness of India stood out before the war.

According to a U.N. Study, in 1936, 67% of the total volume of employment in factories in India was in consumer goods industries, 18% in industries producing intermediates and only 15% in capital-goods industry. Even though steel production increased 8 limes, it was miserably low both in relation to the country’s needs as well as in comparison with the level attained in other countries.

The record output of 8.80 lakh tons in 1935—36 was below the level of Poland in the same year (with a population of less than 1/10 that of India) and less than 1/6 that of Japan in 1936 or 1/19 that of the Soviet Union.

According to Charles Battleheim, the average annual rise in industrial production for the years, 1913—38, was 3.75% which, according to him “was appreciably better than the 2.4% rise in the world production during this period.” That may be so but this rate was, in some respects, slower than that before 1914.

For example, in the seventeen years, 1897—1914, the average daily number of workers in factories increased by 5.30 lakhs; in the seventeen years, 1922—39, it increased by on by 3.9 lakhs. Even in the textile industry where production increased 2 ½ times, the progress was far less in India than in China and Japan.

As R.P Dutt has pointed out, in 1914, India had more than twice as many spindles as Japan and China put together. By 1930, they had totally surpassed India. Again, in 1911 industrial workers constituted 11.7% of the total working population but their proportion declined to 10.3% in 1931.

Thus, the real picture of India on the eve of the II world war was that of ‘De-industrialisation.’ It, in other words, means that the decline of the old handicraft industry was not compensated by the advance of modern industry.

Development of Capitalist Enterprise during the Second World War:

The Second World War dramatically exposed the weakness of India’s industrial structure when even such established industries as textiles, paper, and leather, which require large quantities of Chemicals, found their supplies cut off.

On the other hand, the fall of France, the bombing of British factories, the large-scale sinking of British ships and Japan’s entry into the war made it doubly necessary that India should be developed as speedily as possible into an industrial arsenal for the Allied powers.

The war, therefore, provided a major demand stimulus to Indian industry. New firms, which had entered industry amidst threats of over-production, found a ready market for their products; older firms expanded their sales and almost every industry operated at full capacity.

The high level of operation was caused mainly by the large public outlay which, according to Datar and Patel, increased by 400% between 1939—40 to 1944—45. The Government bought varying but significant proportions of the output of different industries, from a minimum 25% of the cotton textiles output to more than 80% of the cement production.

Among the older industries to expand during the war were cement, cotton textiles, Iron and Steel, and Sugar. Cement being a material for construction, the war generated a considerable expansion in demand for it which was directly responsible for growth.

The paper industry also registered an impressive advance. As with cement, the industry had already grown sizeably before the war and war-time government demand provided a further spurt. Iron and steel industry also grew but less strikingly.

By 1942, Tata’s had expanded steel ingot capacity to a million tons and the steel corporation of Bengal, having entered steel production only in 1940, had built up a capacity of 2.7 lakh tons by 1942.

The cotton textile industry also experienced a Boom which lifted it out of its difficulties. The 1938—39 situation of “Competitive price-reducing pressures” following the spread of the industry to cheaper centres outside Bombay state, was replaced by an expanding demand.

Virtually, the entire domestic effective demand for factory-made textile goods during the war was satisfied by Indian mills. Moreover, Indian mills took advantage of the favourable situation and began penetrating into foreign markets such as Africa, the Near East, and Australia.

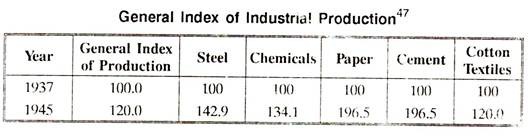

They sought to take the place of Japanese monopolies and, to a certain extent, Lancashire in the textile market. As a result, textile exports increased from 192.7 million yards in 1938—39 to 835.3 million yards in 1942—43. Production of cement and paper in 1945 was 96%, of steel 43% and that of textiles 20% higher as compared with that in 1937.

Apart from the old Industries which expanded their out put, some new industries started production for the first time during the war. These included:

(a) Ferro alloys like Ferro Silicon and Ferro manganese;

(b) Non-ferrous metals and metal fabricating industries like copper, copper-sheets, wires and cables;

(c) Mechanical industries like diesel engines, pumps, bicycles, sewing machines, machine tools had cutting tools;

(d) A few items of textile, tea and oil processing machinery;

(e) And chemicals like caustic soda, chlorine, super-phosphates, Photographic chemicals, and Bi-chromates.

As is to be expected, the number of joint-stock companies increased from 11,114 in 1939 to 14859 in 1945 and their paid-up capital from rupees 290.3 crores to rupees 389 crores. ‘In the first years of the war, there were relatively few new companies but, starting with 1942, their number began to increase rapidly. Over a thousand new companies were formed in 1945 alone.

Mention may also be made of the impetus received by small-scale industries.

Owing to the huge demand for war goods and the comparatively small capacity of large scale industries in India, increasing reliance was placed on the small producer who supplied large and increasing quantities of cotton and woolen goods including blankets, durries, tents, camouflage nets, parachute silk cloth, army boots, leather and rubber goods, glassware, and other small articles like pith hats, socks, and hoses.

A lamentable feature of the war-time industrial development was its lack of balance. The progress made was almost wholly in the consumer industries to the sad and striking neglect of production of capital goods industries. In the words of L.C. Jain, “India could feed and clothe her armies, but she could not equip them.”

The increase in production was brought about, by and large, by fuller utilisation of idle capacity through additional shifts and through more efficient utilisation of capacity in other ways.

Due to want of proper maintenance and replacement, the capital equipment was strained to the maximum leading to heavy wear and tear.

Divetia and Trivedi calculated that “in 1938—39, the total value of machinery and other equipment was equal to about rupees 239 crores. At 5% annual depreciation, the drop in value during the war years would amount to rupees 71.6 crores if the equipment is assumed to have been in use for one shift only. Many industries were, however, working several shifts. If then, it is assumed that industry, as a whole, worked on average for one and a half shifts per day, the depreciation for the war years was equal to rupees 197.5 crores (at 1938—39 prices) or, in other words, nearly 45% of all the machinery and other equipment suffered depreciation and went of operation.”

This wear and tear of capital equipment was one that of results of the inflationary methods which characterised the war economy of India.

War production had to offer high profits in order to best mobilise the limited resources of a country with a low economic potential. High cost of production, based on maximum use of capital equipment and improvised methods, left a legacy of inflation which had not exhausted itself even after Independence.

In this respect, India’s economy differed from that of U.S.A., Australia, and Canada or other countries in which the existing economy could be more easily geared to the war effort.

Despite an impressive increase in the output of selected industries, the overall expansion of industrial output was not very significant, being hardly 20% during 1937—45. This small progress pales into insignificance before the industrial expansion registered in America or Australia.

The U.S. Index of industrial production (Base 1938) moved from 96 in 1939 to 208 in 1944 while that in Canada moved from 101 in 1939 to 184 in 1944. What is more significant is that industrial expansion in India was confined to two or three industries while in the U.S.A., it was all-round, not excluding even consumer goods industries.

Australia did even one better. In 1932, when she was hit hard by the world economic depression, Australia did not produce an ounce of steel. In 1941, she produced 1.5 million tons…more than India’s production that year.

The relatively small increase in industrial production in India during the war was due to the inelasticity of supply of paint and machinery. Preoccupation of allied countries with the war, danger of enemy submarines and non-availability of shipping precluded this possibility. Besides, the existing Indian plant and machinery was sadly out of date.

The real reason, however, lay in India’s lack of power to control her own economic destiny. As Dr. Lokanathan observes:

“The contrast between India, Australia, and Canada was striking. Starting from an initially worse position than India, Australia increased her steel production rapidly and within two years, was able to manufacture air-craft, wireless, and other articles directly through government effort and also by inviting British, American, and other industrialists to set up factories to replace imports. In Canada, the govt., created seven govt., owned corporations for manufacturing planes, shells, rifles and instruments, one for producing machine tools and two for purchasing vital war commodities. In India, even the manufacture of loco-motives, already recommended by an expert committee and for which blue prints were ready, was given up at the last moment on the ground that “it was more desirable to import them from outside.”

Similarly, the proposal to manufacture automobiles in India, which was placed before the govt., as early as 1936, was turned down on the ground of ‘difficulties created by the War.’

Proposals about building up the shipping industry were turned down by the Board of Trade in England who refused to render any help in the promotion of ship-building in India as part of its war effort. There is no doubt that, despite the stress and strain of the war, Great Britain was still dominated by economic interest in her relations with India.

The Eastern Conference, the Grady Mission, and the appointment of a number of technical missions may be regarded as war measures forced upon a reluctant government which could never imagine, much less accept, and industrialised India No wonder, that the reports of many of these committees were not even made available to the public.

We may, therefore, conclude that, mainly because of Great Britain’s attitude— an attitude of keeping India a backward colonial country—India came out of the war much poorer than she entered it. As the Eastern economist puts it, “We could make everything and yet nothing. We were just suppliers of any thing and everything, menders, repairers of all things on earth, but the makers of none. We had no system, no plain.”

Not only was the opportunity of building Indian economy thus lost but, as a result of the war-time strain, the economic situation in India during the post-war years was marked by increasingly critical conditions, soaring inflation, rising prices and mass distress.

Development of Capitalist Enterprise, 1946-1966:

The immediate post-war period was characterised by political uncertainty, communal riots, influx of millions of refugees, and a general disruption of the economy that followed the partition of the country. The overall atmosphere was, therefore, far from favourable for industrial development.

India’s two leading industries, cotton and jute textiles, suffered heavily because the partition cut-off the sources of most of their raw-materials. With all the jute mills within India, she was left with only 19% of the raw jute production. In respect of cotton textiles, the position was no better as India had 99% of the mills with only 60% of the raw-cotton.

Inflation and political strife pushed industrial unrest to new heights strikes and lock-outs were rampant. It was only around 1950 that the country’s economy turned the corner and the First Five Year Plan was launched in April, 1951.

In the First Five Year Plan, investment in industries was rather under-emphasised. Out of a total public sector outlay of rupees 1960 crores, about rupees 74 crores or 4% of the total was spent on industries as a result of which industrial production rose at a compound rate of 5 ¾ % per year.

A major portion of this increase was obtained by better utilisation of idle capacity. The real achievement of the plan, however, was to lift the atmosphere of uncertainty from the country.

The turmoil of the immediate post-It dependence period was over; two good harvests in succession had improved the supply position of the economy; industrial out put had registered a record increase during the calendar year 1955. The stage was thus set for ‘big leap’ forward.

India’s drive for industrialisation began in real earnest only with the Second Plan. Out of a total public sector outlay of rupees 4600 crores, as much as rupees 1074 crores or 24% was spent on industries and minerals. Most of this investment went into basic metals, machine building, and other heavy industries. Overall industrial production increased at the compound annual rate of 7 ½ %.

What is more significant, most of this new increase came from new capacity installed during the period.

Notwithstanding the difficulties faced during the second plan, the Third witnessed a bolder effort to push the tempo of industrialisation. 30% of the total outlay, public as well as private, went to industries. There was, however, a distinct slackening of effort towards the closing year of the Plan.

Vagaries of monsoon dis-organised agriculture while the uncertainty of foreign aid dis-organised the industry. The situation was made more difficult by inflation and mounting costs. Despite these handicaps, the annual growth rate turned out to be 8.2%.

Throughout the ups and downs of the Pans, certain broad achievements clearly stand out. The overall increase in production was impressive. The index of industrial production increased from 54.8 in 1951 (1960 = 100) to 152.6 in 1966. In other words, industrial output in 1966 was more than 2 ½ times as large as in 1951.

A more heartening fact about the industrial development was the vast diversification of the industrial structure. In 1950-51, India had just a few well established industries such as cotton textiles, jute goods, tea, vanaspati, soap, matches, and of course, iron and steel. Some quantities of other products like chemicals, light engineering goods were also produced though on an insignificant scale.

During the planning era, especially since the beginning of the second plan, there was a clear shift away from consumer goods industries and towards basic and heavy industries. As a consequence, the allocation, as a proportion of planned expenditures in industry, to metal, machinery and Chemical industries was 70% in the Second and 80% in the Third Plan.

This shift in investment strategy resulted in a striking growth of output and value-added in basic industries, Leading to a marked change in the output composition of the organised industrial sector. Between 1950—51 to 1965—66, the increase in the output of consumer goods industries was 87%, that of inter-mediate goods by 593% but of machinery by 922%.

Some of the industry groups which recorded spectaculor increases in output were: Chemicals, (4 times), metal products (7 times), electricity generation equipment (6 times), electrical machinery (9 times), transport equipment (8 times) non-electrical machinery (13 times) and Petroleum products (18 times).

Another indication of India’s changing industrial structure is provided by the relative share of machinery and intermediates in the total industrial output of the country. During 1950—51 to 1965—66, the share of the machinery group in the total output rose from 8% to 22%; the share of intermediate goods went up from 23% to 43% while that of consumer goods declined from 68% to 34%.

Along with the increase in and diversification of production, there was also an improvement in the techniques of production. This is evident from the index of electricity consumption per worker which increased from 100 in 1951 to 1322 in 1965—66.

This more than 3-fold increase in the electricity consumed per industrial worker is a telling indicator of the increase in the sophistication of the capital equipment in the Indian industries.

However, the most outstanding feature of the industrial\development in the post-Independence period was the emergence of the public sector as an important lever of economic growth. At the time of Independence, there was no separate category of government companies in the statutory sense.

But, by the end of the Third Plan, the total state investment in public sector enterprises came to rupees 2415 crores and the number of units established reached 74. The state sector dominated such key sectors as steel, petroleum, power generation, fertilisers, electrical equipment, machine tools etc.

Impressive as the overall industrial advance appears, its pace was both slow and inadequate. As against the 7.2% compound annual rate of growth registered in India between 1955—65, North Vietnam’s industry grew at the rate of 20.3% per year between 1953—1966, of U.A.R, by 16.5%, of North Korea by 15.6%. (1948—1966.) Even Pakistan registered a better 13.1% growth rate between 1953—1966.

Another indicator of the slow pace of industrial progress lies in the fact that the number of workers in the secondary sector of economic activity accounted for 10.6% of the total labour force of the country in 1951. By 1961, it went up to 11.7%.

In other words, in the course of decade, the share of this key sector went up by 1.1% age points only. The slow pace of industrial development is also indicated by the share of industry in the National income which went up from 17% in 1948-49 to just 20% in 1966.

Not only was the pace of progress slow, in certain vital fields, it was as yet totally inadequate. Among the major items, for the manufacture of which adequate capacities had not been developed, may be mentioned copper, alloy and special steels, fertilisers, mineral oils and petro-chemicals.

Nowhere was our industrial development more inadequate than in the field of employment. Between 1951—61, India’s labour force increased by 4.7 crores. During the same period, factory employment increased by only ten lakhs.

In other words, hardly 2% of the new entrants to the labour force could be absorbed in the factory sector. The remaining 98% had to manage their livelihood in other sectors or join the swelling army of the unemployed. The occupational structure, by and large, remained unchanged much as in the previous century.

Another major drawback was the extreme unevenness of the regional distribution of this development. As the Fourth Plan says, “in-terms of development, there has been a natural tendency for new enterprises and investments to gravitate towards the already over-crowded metropolitan areas because these are better endowed with economic and social infra-structure.”

The result of this regional imbalance can be seen in the fact that the state of Bengal alone accounted for 21% of the value of industrial output in 1965. In contrast, the six states in Orissa, Kerala, Andhra, Rajasthan, U.P., and Bihar together accounted for 25% of the value of the output.

Yet another negative aspect was the creation of a large number of industrial enterprises producing consumer goods which are not of much economic importance and which are of use mainly to richer classes. These enterprises often used imported semi-products, some-time only assembling and conditioning them.

Many of these firms were set up with the aid of foreign capital. This “Pseudo- industrialisation” took place outside the context of plans and was clearly contrary to plan specifications. Another development, fraught with far-reaching consequences, was the emergence of giant-size companies. Not only did their number increase but the average size also went up.

In the 8 years 1959—66, fresh investment by 20 large industrial houses accounted for 40% of the total additional investment in the private organised industrial sector. Their assets increased from rupees 650 crores in 1958 to rupees 2310 crores as on 31 Dec. 1966.

The Phenomenal growth of ‘giganticism’ may be attributed to two important factors, namely:

(a) The industrial licensing system which worked in such a way as to provide a disproportionate share in the newly licensed capacity to a few concerns belonging to the large industrial houses; and

(b) Provision of assistance by the financial institutions which was so manipulated that 73 industrial houses took away 56% of the total assistance provided by these institutions during the second and Third Plans.

To sum up. The period, 1946—66, was marked by substantial industrial development but there is no doubt that much more could have been done. In particular, a near doubling of the rate of industrial development was a must if India was ever to achieve a decisive transformation of her economy.

And this was not beyond her capacity. The only thing lacking was “the required national will and leadership which alone could transform the possibility of a vigorous and self-reliant industrial development into a reality.”