In this article we will discuss about:- 1. Meaning of Stop Watch Time Study 2. Procedure of Stop Watch Time Study 3. Equipments.

Meaning of Stop Watch Time Study:

Stop Watch Time Study is one of the equipment used for Time Study. It is employed for measuring the time taken by an operator to complete the work. Stop watch used for time study purpose should be very accurate and preferably be graduated in decimals so that it can recover even up to 0.01 minute.

A large hand in the stop watch is revolved at a speed of one revolution per minute. The dial of the stop watch is divided into 100 equal divisions. The small hand inside the stop watch revolves at a speed of one revolution in 30 minutes.

Procedure of Stop Watch Time Study:

The stop watch procedures for collecting Time Study Data are listed below:

ADVERTISEMENTS:

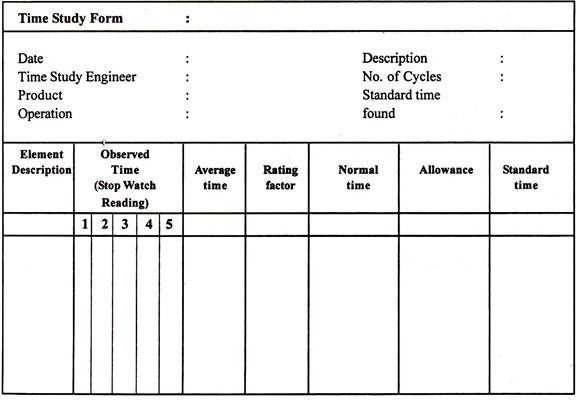

a) Analyse the job to establish the quality to be achieved in the job.

b) Identify key operations to be timed in the job.

c) Get improved procedure from the method study department.

d) Organise resources and explain the objectives of time study to the worker and supervisor.

ADVERTISEMENTS:

e) Explain details to worker about improved working procedure.

f) Break operation into elements to separate the constant elements from variable elements.

g) Observe and record the time taken by an operator.

h) Determine for number cycles to be timed and then the average time or representative time can be found out.

ADVERTISEMENTS:

i) Rate of performance of the worker during observation.

j) Calculate normal time from observed time by using performance rating factor.

k) Add process allowance rest and personal allowance and special allowances to the normal time in order to obtain standard time or allowed time.

l) Standard time determination by adding normal time and allowances.

Equipments of Stop Watch Time Study:

Stop watch is one of the important timing devices used for measuring the time taken by a worker to complete a job. Stop watch is an accurate time measuring equipment which can normally run continuously for half an hour or one hour and record the time by its small hand. One revolution of the big hand records one minute. Even the scale covering one minute may be calibrated into intervals of 1/ 100th of a minute.

There are three types of stop watches and they are:

1. Non-fly back stop watch,

2. Fly back stop watch, and

3. Split hand or split second type stop watch.

ADVERTISEMENTS:

1. Non-fly back stop watch:

This stop watch is used for continuous timing. When the winding knob is pressed for the first time, the watch starts and the long hand begins to move, now if the winding knob is pressed for the second time, the long hand stops. If the winding knob is pressed for the third time, the hand returns to zero position.

2. Fly back stop watch:

When two elements are to be timed and the second element is immediately after the first element, fly back stop watch is required. In a fly back stop watch, the watch is started and stopped with the help of a slide.

ADVERTISEMENTS:

By pressing the wind knob, the hands are brought back to zero, but they move forward again immediately without stopping. To stop the hand at any point, the slide is used. This watch is used to take continuous timing observation.

3. Split-hand stop watch:

A split hand stop watch is used to get greater accuracy when two elements are to be timed and the second element is immediately after the first element. The stop watch is started and the first element is observed.

After the completion of first elements the winding knob is pressed which makes one hand to stop but the other hand keeps moving. After the reading has been taken for the first element, the winding knob is pressed for the second time which restarts the stopped hand making the two hands go together.

ADVERTISEMENTS:

Performance rating plays the most important role in the process of setting standard time. Performance rating is used to determine “fair day’s work”. When a group of workers are doing the same job, the common question will be “Is an individual worker doing rapidly or is he taking more time intentionally?”. The solution to the question is “Performance rating”. Thus rating means gauging and comparing the pace rate or the performance of a worker against standard performance level set by the time study engineer.