The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3. Man-Machine Chart 4. Left-Right Hand Chart 5. Simo-Chart.

Type # 1. Operation Process Chart:

This is a graphic representation of the sequence of all operations and inspections involved in the process. In this chart, all components or materials entry points are indicated by the horizontal lines and the processing of these materials are shown vertically. Operation process charts provide a compact overall view of the whole system of operations involved in the manufacture of a product.

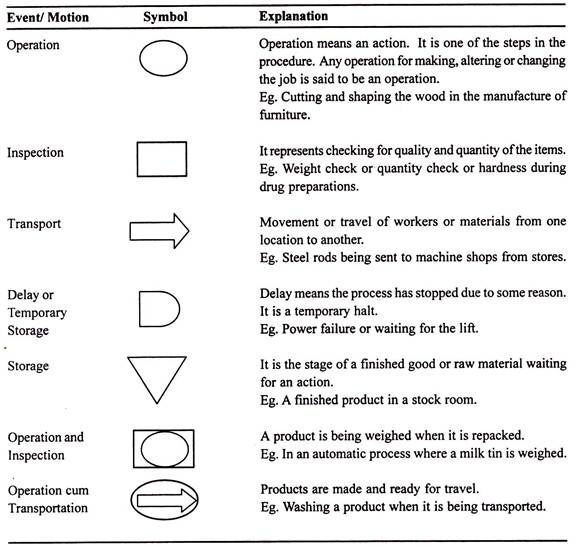

Process Chart-Symbols:

In the process charts sequence of events are portrayed diagrammatically by means of a set of process chart symbols to help a person to visualise a process as a means of examining and improving it.

ADVERTISEMENTS:

The basic symbols used in the process chart to record the various types of events are as follows:

The first five symbols are basic symbols and the last two combined symbols. The combined are used to represent the combined activities, the outer symbol represents major activity.

Types of Process Charts:

ADVERTISEMENTS:

There are three types of process charts and they are:

i) Outline process chart.

ii) Two handed process chart.

iii) Flow process chart.

ADVERTISEMENTS:

i) Outline Process Chart:

An outline process chart is the first step to a detailed analysis of a process. It gives the overall view of the whole process by recording in sequence only the main operations and inspections. It uses only operations and inspection symbols.

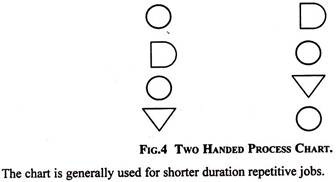

ii) Two Handed Process Chart:

The two handed process chart gives a synchronised and graphical representation of the sequence of manual activities of the worker. It is called two handed process chart since it records the activities of the left hand and the right hand of the worker as related to each other. A time scale can also be provided on the chart. This chart is used for repetitive works of short duration.

iii) Flow Process Chart:

A flow process chart records all the events in sequence using process chart symbols and marks distance and time taken for completing an activity.

There are three types of flow process charts and they are:

i) Flow Process Chart (Men).

ii) Flow Process Chart (Material).

ADVERTISEMENTS:

iii) Flow Process Chart (Equipment).

The Flow Process Chart for Men records the activities of an operator.

The Flow Process Chart for Materials records what happens to the material with respect to location and condition.

The Flow Process Charts for Equipment record the manner in which the equipment is used.

Type # 2. Flow Diagram:

ADVERTISEMENTS:

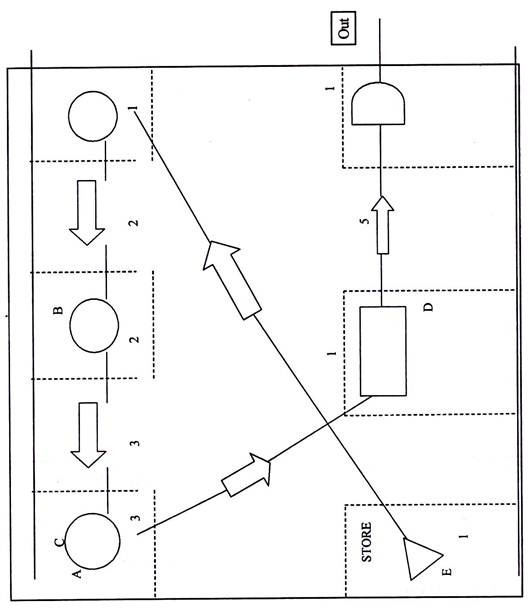

A flow diagram is the simplest of all the devices in this class of technique. It is the plan view of a work to a certain scale and link diagram indicating the path followed by the object under study. It gives an overall view of an existing or proposed process and is used for making improvements. It shows the path followed by the material, man and equipment.

The steps involved in drawing a flow diagram:

i) The plan of the work area is drawn to scale.

ii) The relative positions of various facilities such as machines, stores, area of inspection and the like are marked.

ADVERTISEMENTS:

iii) The actual path movements of a worker or material along with the direction of movement is indicated. For better understanding of different movements, different colours and process symbols may be used.

The above following shows a flow diagram in that material from stores move to place ‘A’ where one operation is performed. Thereafter the semi-finished product is sent to ‘B’ where another operation is conducted. After that it is moved to place ‘C’ wherein yet another operation is conducted. Then it is sent to place ‘D’ for inspection. Thereafter it is sent to place ‘E’ where it halts for some-time and finally goes out of the factor.

String Diagram:

A string diagram is a special form of flow diagram in which a string is used in place of lines to measure distance. This diagram is a layout drawing on which a length of string is used to record the extent as well as the pattern of movement of a worker or piece of equipment working within a limited area during a certain period of time. It is used to study where the journeys are irregular in distance and frequency, otherwise it will be difficult to see exactly what is happening.

It is used to investigate movement in the following situations:

ADVERTISEMENTS:

1. When a group of operators is working.

2. When a single operator is attending several machines.

3. In processes where several sub-assemblies have to be moved to other assembly.

4. Where processes require the operator to be moved from one work place to another.

5. For checking the relative values of layouts.

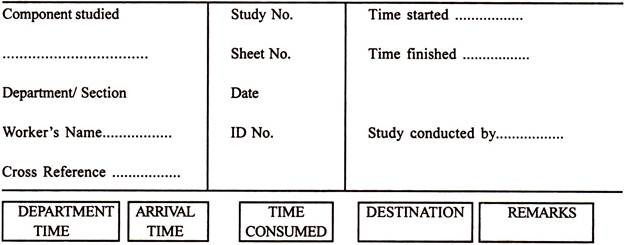

String Diagram Study Sheet:

ADVERTISEMENTS:

To draw a diagram first, study is made for the movements in the activity concerned. Every movement in the performance of the work is recorded on the study sheet.

The string diagram study sheet contains the following details:

Most of the string diagrams consist of a scale plan mounted on a soft board, with pins stuck in the relevant work stations. Additional pins to be driven in where the direction or moves between these points change. Thread of different colours can represent the various factors being moved.

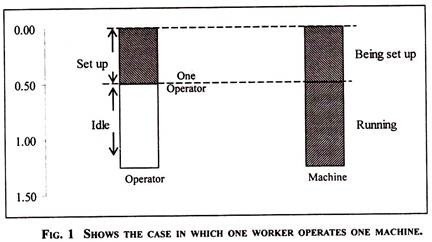

Type # 3. Man-Machine Chart:

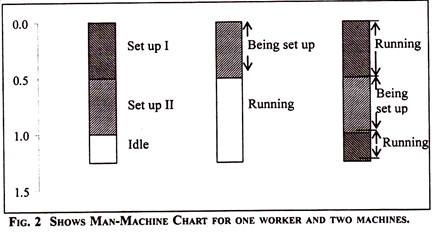

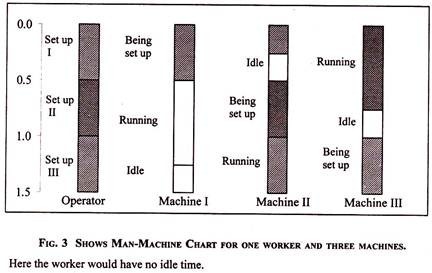

This chart explains graphically the activity of a man and machine he is attending with reference to a time scale. This study is undertaken to find what number of machine each worker can operate or how many workers can work on each machine.

This chart enables the management to minimise the idle time of the worker and to use the machines to their full capacity. For example, there are three workers and each worker is doing the same operations on machine. In that the time to set up a machine cycle is 0.50 minutes and machining time taken 0.75 minutes.

From the figure it is clear that for each operation, the worker is idle for 0.75 minutes, when the machine is running. For this, the alternative can be to put two machines and let allow one worker to work both on them.

Now the worker still remains idle for 0.25 minutes in each operation. In order to minimize this, one more worker is allowed to work on three machines.

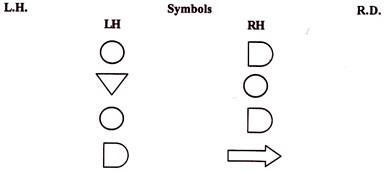

Type # 4. Left-Right Hand Chart:

This is also known as two handed process chart. It gives a synchronized and graphical representation of the sequence of manual activities of the worker. This type of chart is used to improve the motion sequence of an operator.

It is called two-handed process chart since it records the activities of the left hand and the right hand of the worker as related to each other in a two column chart by means of symbols aligned representing the simultaneous movements of both hands appear opposite to each other. The chart is used to minimize the unnecessary motions and to arrange the remaining motions in an economical way.

ADVERTISEMENTS:

The two handed process chart is given below:

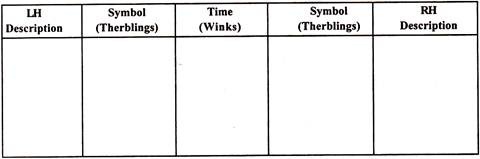

Type # 5. Simo-Chart (Simultaneous-Motion Chart):

Simo-Chart is an extremely detailed two hand chart. A Simo-Chart is often based on film analysis. It shows a common scale the Therbling or groups of Therblings performed by different parts of the body of one or more workers. The time scale is represented in winks (1/2000 of a minute).

Simo-Chart is used for micro motion analysis, for example short cycle repetitive jobs like inspection, packing etc., and high order skilled jobs like component assembly. A Simo-Chart shows the relationship between different limbs of a worker with records of duration of micro motions. For example, at an instant it can be found what one hand is doing with respect to another in terms of therblings.

Steps for Constructing Simo-Chart:

1. Using a 16 mm movie camera micro motions are filmed as the worker performs the job. A wink counter i.e., a timing device is placed in the field of view.

2. The film thus obtained after a whole cycle, is viewed for analysis.

3. The work study engineer analyses the film, frame by frame concentrating first on the left hand and then on right hand movements.

4. The data noted in step-3 is recorded in the form of therbling chart. The duration of actual movements are also read from the wink counter.

5. A Simo-Chart is prepared at this stage for further study and analysis.

6. This Simo-Chart of the existing method is subjected to a questioning procedure based on the principle of motion economy. The purpose is to develop a better and improved procedure.

7. A new Simo-Chart is now prepared for the new method.

8. The new method is now checked to claim its advantages over the old method.

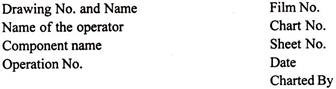

Simo-Chart contains the following details:

A Simo-Chart is advantageous because it permits very accurate and detailed analysis. The work cycle from the film can be studied at ease, peacefully and away from the disturbing surroundings of the work place. However this technique is limited because of high cost of filming and analysis.