The below mentioned article provides an overview on Lower Capacity Utilisation in Industries. After reading this article you will learn about: 1. Subject-Matter of Lower Capacity Utilisation 2. Factors Responsible for Lower Capacity Utilisation 3. Measures to be Followed.

Subject-Matter of Lower Capacity Utilisation:

Industrial sector in India, in general, is suffering from the problem of under-utilization of plant capacity. Although there are differences in estimates of under-utilization of capacity of Indian industries but these estimates may largely vary from 20-30 to 60-70 per cent. But it can be assumed safely that the average level of capacity utilisation in various Indian industries fluctuate in and around 50 to 60 per cent.

This lower capacity utilisation of industries has been reflecting in the higher cost-structure of industrial production and also in increasing incremental capital-output ratio (ICOR). Both these higher cost structure and increasing ICOR have been responsible for lack of competitiveness of Indian industries in the international market.

This problem of under-utilisation of plant capacity is very much acute in the power sector where the capacity utilisation is at best on and around 25 to 35 per cent of total installed capacity. In 1990-91, total installed plant capacity of power sector was 74.7 GW whereas the volume of energy generated was to the extent of 289.4 TWH.

ADVERTISEMENTS:

In 1995-96 the same figure increased to 94.5 GW and 415.5 TWH respectively. The Plant Load Factor (PLF) showing operational efficiency of thermal power plants in India reveals that the average PLF was 7.1 per cent in 1992-93 and 63.0 per cent in 1995-96.

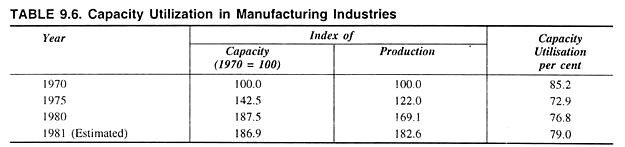

Manufacturing industries are also suffering from low capacity utilisation. Table 9.6 shows that the manufacturing industries in India has been confronting with the problem of decline in capacity utilisation from 85.2 per cent in 1970 to 72.9 per cent in 1975 and then to 76.8 per cent and 79.0 per cent in 1980 and 1981 (estimated) respectively.

Thus, the above Analysis of the capacity utilisation rate for various products during 1992-93 by the ICICI shows that the average rate declined by 1.1 percentage points for basic goods (from 84.8 per cent to 83.7 per cent), by 0.8 percentage points for intermediate goods (from 75.9 per cent to 75.1 per cent) and by 8.6 percentage points for consumer durable (from 63.7 per cent to 55.2 per cent).

ADVERTISEMENTS:

However, the capacity utilization rate for capital goods and consumer non-durables increased by 1.4 and 0. 8 percentage points, that is from 64.1 per cent to 65.5 per cent and from 48.8 per cent to 79.6 per cent respectively.

In recent years, the capacity utilization in Steel Authority of India Limited (SAIL) is one of the best among various public sector enterprises of the country. The SAIL closed the 1994-95 with a capacity of 10 1 per cent, up from 98 per cent achieved during 1993-94. Apart from this, the SAIL has achieved the highest production and sales, clubbed with the lowest specific consumption of energy, coke and petro-fuels.

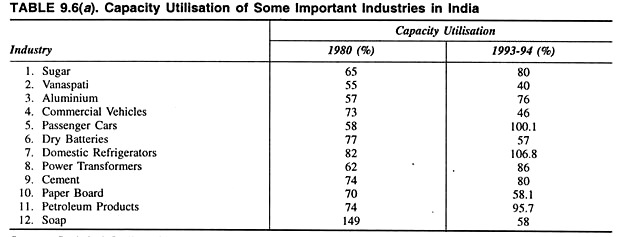

The capacity utilisation of consumer goods industry, basic goods industry and intermediate goods; industry is also having its varying degree. Table 9.6(a) shows capacity utilisation of some important industries in India.

Table 9.6(a) reveals that while the capacity utilisation of sugar industry has increased from 65 per cent in 1980 to 80 per cent in 1993-94, but that of vanaspati industry has declined from 55 per cent to 40 per cent during the same period. Again the production capacity utilisation of commercial vehicles and dry battery industries has declined from 73 per cent and 77 per cent in 1980 to 46 per cent and 57 per cent respectively.

ADVERTISEMENTS:

Again the production capacity utilisation of passenger cars and domestic refrigerators industries has also improved from 58 per cent and 82 per cent respectively to 100.1 per cent and 106.8 per cent respectively. Again the production capacity utilisation of power transformers and cement in India has also improved from 62 per cent and 74 per cent in 1980 to 86 per cent and 80 per cent respectively in 1993-94.

While the capacity utilisation of paper and board industries and soap industries have declined from 70 per cent and 149 per cent in 1980 to 58.1 per cent and 58 per cent respectively in 1993-94.

Thus, it is found that while the capacity utilisation of sugar, aluminium, passenger cars, domestic refrigerators, power transformers, cement and petroleum products industries have been improving but the capacity utilisation of other industries like vanaspati, commercial vehicles, dry batteries, paper and board and soap industries have declined considerably.

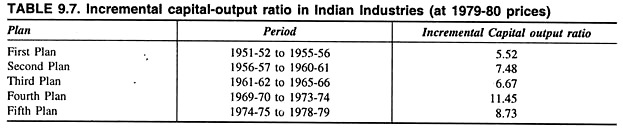

All these have been resulting in an increase in the value of incremental capital output ratio (ICOR). Table 9.7 shows that the value of ICOR which was 5.52 during the First Plan, has gradually increased to 7.48 per cent during the Second Plan and then to 11.45 per cent during the Fourth Plan.

The same ratio then declined to 8.73 per cent during the Fifth Plan. This high value of ICOR and its increasing trend clearly reflect on the decline in the capacity utilisation.

Moreover, due to this lower capacity utilisation the cost structure and the cost level of Indian industries remained all along very high. This has been reducing the cost efficiency of these projects and also reduced the degree of competitiveness of Indian industries.

ICICI Study on Capacity Utilisation, 1995-96:

The Industrial Credit and Investment Corporation of India (ICICI) in its study entitled “capacity utilisation in the private corporate sector 1994-95 and 1995-96” observed that the capacity utilisation by private corporate sector showed an overall improvement of 3.57 per cent during 1995-96.

ADVERTISEMENTS:

The main contributors to this improvement were the capital goods and basic goods industries for which the capacity utilization rate improved by 11.63 per cent and 5.03 per cent respectively.

The study, based on a sample of 975 ICICI assisted companies which provided data on 2,034 products, said the rate increased moderately for the consumer durables and intermediate goods industries by 1.97 per cent and 1.12 per cent respectively, but declined marginally by 0.92 per cent for the consumer non-durable goods industry.

ICICI studies on capacity utilization carried out during the post-reform period clearly indicate a gradual recovery in the physical production and capacity utilization of the ICICI sample companies since 1993-94. A significant feature of this recovery is the consistently high growth rate recorded by the capital goods sector, ICICI said.

The analysis of the real investment growth shows that the rate increased by 20.2 per cent during 1995- 96 for the ICICI sample companies. Within this sample, the rate of growth of real investment was highest at 48.8 per cent for the capital goods, followed by 36.6 per cent for the basic goods industry, ICICI said.

ADVERTISEMENTS:

The analysis of the growth of actual production reveals that during 1995-96, the production growth for the sample companies was 29.5 per cent, far exceeding the growth of the manufacturing sector as a whole (13 per cent).

This growth was spearheaded by the capital and basic goods industries which grew at 88.9 per cent and 43.4 per cent respectively.

For the registered manufacturing sector as a whole, the capacity utilization (based on the method developed by the US National Board of Conference) according to ICICI, increased by 4.8 per cent during 1995-96. The capacity utilization rate of this sector had declined continuously between 1990-91 and 1993-94.

The analysis of the loss of production due to unutilized capacity indicates that the market value of the net loss of production of ICICI sample companies increased by Rs 3,010 crore, ICICI observed.

Factors Responsible for Lower Capacity Utilisation:

ADVERTISEMENTS:

Following factors are responsible for lower capacity utilisation of Indian industries:

1. Deficiency in basic infrastructure:

The most important factor responsible for this lower capacity utilisation is the deficiency in the basic infrastructure such as power, coal and transportation facilities. In the absence of regular and assured supply of power and coal, the two prime sources of energy, the industries in India sometimes had to work at lower level than its permissible capacity.

2. Lack of Demand:

Inadequate demand is also a responsible factor for lower capacity utilisation of Indian industries. Industries like cotton textiles, motor vehicles light vehicles (scooter, motor cycle etc.) have been facing the problem of inadequate demand and thus have been working under capacity deliberately.

3. Worsening Industries Relation:

Another important factor which is very much responsible for this low capacity utilisation is the worsening industrial relations. Due to bad industrial relations (industrial disputes), a huge loss of man-days have been taking place. This loss of man-days increased significantly from 11.7 million in 1976 to 44 million man-days in 1979.

Again this loss of total man-days remained as high as 29.4 million in 1985, 34.12 million in 1991-92 and 17.43 million in 2007-08. Most of loss of man-days is due to strikes and lockouts.

4. Faulty Design and Technical Faults:

Under-utilisation of existing capacities of Indian industries has also been resulting from faulty designs of boiler; erection, installation etc. and also due to continuous technical faults in the operation of projects which might be resulting from lack of proper maintenance and monitoring.

Measures to be Followed:

ADVERTISEMENTS:

Thus in order to improve the degree of capacity utilisation of Indian industries following steps must be taken:

(a) Removing the deficiency and bottlenecks in the supply of basic infrastructural facilities like power, energy and transport;

(b) Removing the major causes of industrial strike, such as wages and other allowances, personnel and retrenchment and indiscipline;

(c) Overcoming the stagnation in productivity by improving the incentives to work and also by reducing the degree of industrial disputes;

(d) Providing budgetary relief in excise and custom duties for raising the demand for various products produced by manufacturing industries through price cut;

(e) removing all technical faults and making necessary correction in the design of future projects; and lastly, sincere participation of all categories of workers, technicians, executives in redressing all different problems faced by these industries can pave the way for near a full capacity utilisation of these industries.

ADVERTISEMENTS:

The Seventh plan had also set an objective in this regard which mentioned to promote efficiency and productivity through elimination of infrastructural bottlenecks and shortages by improving capacity utilisation and by promoting modernisation of plant and equipment and more extensive application and integration of science and technology.

In recent years, steps have been taken by the Government to remove the recessionary conditions faced by Indian industries through the introduction of various economic reforms. After attaining a negative growth rate in industrial production in 1991-92, the year 1992-93 has reported a positive growth rate of about 4.6 per cent.

This positive growth rate attained in 1992-93 is noteworthy as it signifies that these industries may have been able to withstand important competition and may be internationally more competitive as a result of modernisation and upgradation of their production capacities undertaken during the last two years (1990-91). This represents a significant improvement from the past.