Let us make in-depth study of the meaning, incidence, nature, factors causing of industrial sickness.

Meaning of Industrial Sickness:

The strength of the industrial sector, by and large, determines the soundness of the economy.

A developing economy like India cannot afford the growing sickness in industries as it results in a colossal wastage of physical, financial and human resources. In the presence of the resource crunch, the industrial sickness becomes all the more an alarming problem. Industrial sickness usually refers to a situation when an industrial firm performs poorly, incurs losses for several years and often defaults in its debt repayment obligations.

The Reserve Bank of India has defined a sick unit as one “which has incurred a cash loss for one year and is likely to continue incurring losses for the current year as well as in the following year and the unit has an imbalance in its financial structure, such as, current ratio is less than 1: 1 and there is worsening trend in debt-equity ratio.” The State Bank of India has defined a sick unit as one “which fails to generate an internal surplus on a continuous basis and depends for its survival upon frequent infusion of funds.”

ADVERTISEMENTS:

However, prior to the enactment of Sick Industrial Companies Act (SICA) in 1985, there was no agreement on the criteria to be used to describe an industrial unit as sick. According to SICA, as amended in 1992, an industrial company can be declared as sick which has at the end of any financial year accumulated losses equal to or exceeding its entire net worth. It may be noted that Sick Industrial Companies Act (SICA) applies to registered companies which have been in existence for at least 5 years.

In case of small scale industrial unit (SSI), it is regarded as a sick unit if it has:

(i) Incurred a cash loss in the previous accounting year and was likely to continue with losses in the current accounting year and further its cumulative cash losses are equal to 50 per cent or more of its peak net worth during the last five years and

(ii) It has defaulted in meeting four consecutive installments of interest.

ADVERTISEMENTS:

According to the Development Commissioner, a small scale industrial unit (SSI) becomes sick if its:

(a) Capacity utilisation is less than 50 per cent of the highest achieved during the preceding five years (incipient sickness)’,

(b) Net worth has been eroded by more than 50 per cent; and

(c) The unit has remained closed for a period more than six months.

ADVERTISEMENTS:

On the basis of the above definitions of a sick industrial unit, it emerges that the symptoms of the sickness of an industrial unit manifest themselves in the form of unbalanced financial structure, erosion of more than 50 per cent of its net worth, absence of the generation of internal surplus, under- utilisation of capacity and survival of the unit upon frequent infusion of funds.

Incidence of Industrial Sickness:

A very disquieting feature of the industrial scenario is the mounting incidence of industrial sickness. It is a matter of deep concern not only for shareholders and creditors of the sick concerns but also to the society at large. There is sickness of industries both in the large-scale sector (i. e., Non- SSI sector) and in the small-scale industries (SSI). Growing incidence of sickness has been one of the pressing problems faced by the industrial sector in India. Substantial amounts of banking funds are locked up in these sick industrial units.

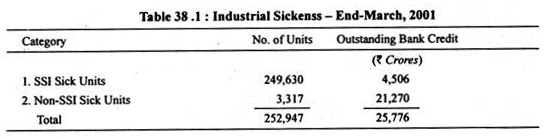

There was a problem of increasing industrial sickness even before the new policy of liberalisation and globalisation adopted in 1991. Thus the number of SSI sick units increased from 58,551 in 1982, rose to 2.21 lakhs in March 1991 and to 2.52 lakhs in end-March 2001. Table 38.1 gives the number of sick industrial units both in the small scale industrial (SSI) sector and non-small scale industrial (non-SSI) and the outstanding bank credit locked in them.

It will be seen from Table 38.1 that though the number of large and medium sick industrial enterprises (i.e., non-SSI sick units) is much smaller than SSI sick units, the outstanding bank credit locked in them is much greater than that in SSI sick units.

It may be noted that in the sick industrial companies, a lot of resources of banks are locked up. The data reveal that as on March 31, 2001, 3,317 non-SSI sick industrial units accounted for an outstanding bank credit of Rs.21, 270 crores. Industry-wise data show that five industries, namely, textiles, engineering, electrical, chemicals and iron and steel accounted for about 56 per cent of total outstanding bank credit.

There has been a phenomenal rise of industrial sickness over the last few years. It is significant to note that sickness has been growing faster in the small-scale sector than in large and medium- scale sectors. At the end of March 2001, there were 252,947 sick units. Out of these, 249,630 were small-scale sick units against whom outstanding bank credit was Rs. 4,506 crores. (See Table 38.1)

Nature and Causes of Industrial Sickness:

Competition breeds efficiency but adversely affects weak industrial units and makes them sick. The clear directional changes since 1982-83 towards liberalisation of industrial licensing policies, foreign collaboration approvals, the concept of minimum-size plants are welcome from consumers’ point of view. But the weaker units have to pay the price. The inevitable cost of achieving competitive efficiency is that the weak must be allowed to fade. But the country cannot allow this to happen.

The Sick Industrial Companies (Special Provisions) Act, 1985, was enacted to help and revive the sick units. The substantive portions of the Act came into force from May 15, 1987. The Act provided for setting up of a quasi-judicial body designated as the Board for Industrial and Financial Reconstruction (BIFR) to deal effectively with the problem of sick industrial companies. The Reserve Bank of India has issued guidelines to banks to strengthen the monitoring system and to arrest industrial sickness at the incipient stage.

Nature of Sickness:

ADVERTISEMENTS:

Sickness in industry can be classified into:

(a) Genuine sickness which is beyond the control of the promoters of the concern despite the sincere efforts by them,

(b) Incipient sickness due to basic non-viability of the project, and

(c) Induced sickness which is due to the managerial incompetence and wrong policies pursued deliberately for want of genuine stake.

ADVERTISEMENTS:

This is a man-made sickness in which some unscrupulous promoters adopt fraudulent practices to start a concern and to get away with the money obtained by fraud and deceit.

The FICCI study entitled ‘Industrial Sickness — Dimensions and Perspectives’ says that the causes of sickness are both internal and external, often operating in combination. External factors are government policies on pricing, duties, taxes, high interest rates, taxes on profit, slackness in demand, sluggishness in export markets, high labour cost, inadequate availability of inputs, lack of infrastructure and the like.

The internal factors which contribute to sickness are wrong planning in relation to location, technology, capital cost, technological obsolescence, management deficiencies and industrial unrest. We explain below these external and internal factors in some detail.

External Factors:

The following are some of the external factors causing industrial sickness in India:

ADVERTISEMENTS:

(i) General Recessionary Trend:

Sometimes a general depression hits industrial units. This is reflected in lack of demand for industrial products in general. An overall slowdown in economic activities affects the performance of individual projects. Improper demand estimation for the products to project lands the industrial units in difficulties.

(ii) High Prices of Inputs:

When the costs of manufacture are high and sales realisation low, the industrial unit cannot stand in the market. This happens when the prices of inputs such as price of fuel such as petroleum during energy crisis goes up whereas the competitive forces keep down the prices of the products.

(iii) Non-Availability of Raw Materials:

When the supplies of raw materials are not available regularly or in good quality, the industrial units are bound to be in trouble. This often occurs in case of supply of imported raw materials.

ADVERTISEMENTS:

(iv) Changes in Government Policies:

The industrial sickness is also caused by certain changes in policy designs of the government. These frequent changes affect the long-term production, financial and marketing planning of an industrial unit. Changes in Government policies regarding imports, industrial licensing, taxation can make viable units sick. For example, liberal import policy since 1991 has rendered many small-scale industrial units sick.

(v) Infrastructure Bottlenecks:

Often the infrastructure difficulty is responsible for industrial sickness. No industrial unit can survive prolonged transport and power bottlenecks.

Internal Factors:

The following are the important internal factors which are often responsible for industrial sickness:

(i) Project Appraisal Deficiencies:

ADVERTISEMENTS:

The industrial unit becomes sick when the unit has been launched without a comprehensive appraisal of economic, financial and technical viabilities of the project.

(ii) Industrial Unrest and Lack of Employee Motivation:

When there is labour discontent, no industrial unit can function smoothly and efficiently. When labour lacks motivation no good results can be expected and this results in sickness and non-viability of several industrial units.

(iii) Wrong Choice of Technology:

If the promoters use wrong technology, results are bound to be unsatisfactory. Many industrial units, especially in the small-scale sector, do not seek professional guidance in installing the correct machinery and plant. If the machinery and plant installed turn out to be defective and unsuitable, they are bound to suffer losses and become sick and non-viable.

(iv) Marketing Problems:

ADVERTISEMENTS:

The industrial unit becomes sick due to product obsolescence and market saturation. The industrial unit becomes sick when its product-mix is not attuned to the consumers’ demand.

(v) Wrong Location:

If the location of an industrial unit happens to be defective either from the point of the market or the supply of inputs, it is bound to experience insurmountable difficulties.

(vi) Lack of Finance:

Inadequate financial arrangements or in the absence of timely financial aid an industrial unit is bound to come to grief. It will not be able to withstand operational losses.

(vii) Improper Capital Structure:

ADVERTISEMENTS:

If capital structure proves to be unsound or unsuitable especially on account of delayed construction or operation, it will result in cost overruns or unduly large borrowing and create financial trouble for the unit concerned.

(viii) Management Deficiencies:

The biggest cause of industrial sickness is the managerial inefficiency. Lack of professional management or experienced management and the existence of hereditary management is an important cause of industrial sickness. Inefficient management results in inability to perceive things in proper perspective devoid of routine considerations. Inefficient management is also unable to build up good team and inspire confidence for an organised collective effort and takes autocratic and high-handed decisions.

(ix) Voluntary Sickness:

There is some sickness which is voluntarily invited by the entrepreneurs for various motives like getting government concession or aid from financial institutions. Thus industrial sickness cannot be attributed to any single, or simple cause but may be the result of a combination of number of allied causes.

An analysis of 637 large-scale units identified that deficiency in management was responsible for 52 per cent cases of sickness. While labour troubles caused sickness only in 2 per cent of the industries, market recession and environmental factors came second with 23 per cent.

The other causes were technical factors and faulty initial planning (14 per cent) and infrastructural factors such as power cuts and shortage of critical inputs (9 per cent). Of the 637 large units, 350 could be put back on the track. Of these, 221 units, with the outstanding credit of Rs. 1,125.06 crores were put under the nursing programme.

Suggestions for Rehabilitation of Sick Units:

The rehabilitation of sick units or restoring them to normal health is a matter of great urgency in view of the serious social, economic and political consequences of industrial illness.

The following measures may be suggested:

(i) Cooperation between Term-Lending Institutions and Commercial Banks:

Since commercial banks provide working capital, they are in a position to know about the working of industrial concern. But assistance from term-lending institutions is also essential for rescue operations.

(ii) Coordination between Various Government Agencies:

All government agencies, both regulatory and promotional, must join hands to restore sick units to health.

(iii) Full cooperation from various suppliers,’ unsecured creditors and other stakeholders, particularly from the employees, is also essential to take the concern out of the difficulties in which it is involved.

(iv) Willing Cooperation and Clear Understanding with the Project Promoters:

Generally there is a lack of trust and confidence among the various interests concerned. It is found that government agencies and dealing institutions are more worried about their money and are anxious to recover them instead of curing of the health of the sick units.

(v) Checking Over-Valuation of Inventories:

The banks should verify on a regular basis the valuation of inventories both in terms of quantity and price. This would prevent over-borrowing on the hypothecation of inventories.

(vi) Marketing:

There should be well organised and scientific marketing by the project promoters otherwise launching of a project will be a leap in the dark. Good marketing arrangements will prevent industrial sickness.

(vii) Recovery of Outstanding:

Every effort should be made to realize outstanding advances so that the concern is able to gather funds to avoid sickness.

(viii) Modernisation of Machinery:

If the sick unit is to be restored to health, old and obsolete machinery and outdated technology should be discarded at the earliest.

(ix) Improving Labour Relations:

Restrictive labour and unreasonable trade unions are great obstacles. Improving labour relations will go a long way in curing industrial sickness.

(x) Efficient Management:

If necessary inefficient management should be replaced. The key to industrial health lies in alert and efficient management. The management should show a calm approach, patience and perseverance, courage and ability to steer in bad weather.

(xi) Performance Incentives:

It is necessary to offer performance incentives to the executives and the workers to induce them to put in their best efforts. This will be quite helpful in curing industrial sickness.

(xii) Sympathetic Government Attitude:

During periods of industrial illness the government agencies should adopt a sympathetic and understanding attitude so that the problem is not aggravated but moves towards a solution instead.

(xiii) Austerity and Economy:

Austerity and disciplines should be enforced at all levels. Every effort should be made in raising funds internally through the sale of excess assets, surplus machinery, etc. Uncalled for tours, lavish entertainments, unnecessary personal expenses should be ruthlessly cut down.

Conclusion:

In view of the large-scale industrial sickness it would be necessary to organize a task force consisting of competent and experienced executives in various branches of business to go into the case and monitor recovery. Rehabilitation of sick units is not an easy and simple affair. An all-round effort is necessary to root out the disease, first necessary step is the identification of sick units which can be made viable through renovation, expansion, and diversification. Units beyond recovery should be wound up.

The second step is the reconstitution of management. Where the management is unwilling or unable to play its proper role, the financial institutions and the government agencies should intervene to fulfill their large social responsibility of ensuring efficient use of national resources. Since industrial sickness is due both to external causes, e.g., general recession, and internal causes like dishonest and inefficient management, the remedy must also lie in both directions.

With a view to meeting the situation, the early warning system is strengthened. Viability studies should be undertaken to identify the sick units including creeping sickness which could be eventually restored to health with additional financial aid on liberal and easy terms. To an extent increase in industrial sickness is inevitable result of the very process of modernisation or technological development industry. It is natural that the units which cannot keep pace with the ongoing technological change will become sick, they should be allowed to wind up.