In this essay we will discuss about the Cotton Textile Industry in India. After reading this essay you will learn about: 1. Subject Matter of Cotton Textile Industry 2. Problems of Cotton Textile Industry in India 3. Remedial Measures.

Contents:

- Essay on the Subject Matter of Cotton Textile Industry

- Essay on the Problems of Cotton Textile Industry in India

- Essay on the Remedial Measures for Solving the Problems of Cotton Textile Industry

Subject Matter of Cotton Textile Industry:

The cotton textile industry is one of the oldest and firmly established major organised industries of India. In 1818, the first unit of cotton textile industry was established at Fort Gloster, situated near Kolkata. Later on, real base of this industry was established in 1854 with the establishment of another cotton textile mill at Mumbai.

Till 1920 this industry was continued with its units in and around Mumbai. Later on, this was expanded to Tamil Nadu, Karnataka, Madhya Pradesh, Northern India and some other parts of the country. But at present Mumbai and Ahmedabad are the two major centres of cotton textile industry in India. The other important centres for the production of textiles are Sholapur, Kanpur, Kolkata, Nagpur and Indore.

ADVERTISEMENTS:

The textile industry continues to be the largest industry in our country. It accounts for 20 per cent of total industrial output, provides employment to 20 million people and contributes nearly 38 per cent to the total Value of exports. The textile industry has witnessed a phenomenal growth during the last four decades.

The spindle-age in the cotton/man-made fibre textile mills increased from 110 lakh in 1951 to 322 lakh in January 1997.

The cotton textile industry in India is having its three following distinct categories in the organised Sector:

(a) Spinning mills,

ADVERTISEMENTS:

(b) Coarse and medium composite mills, and

(c) Fine and superfine composite mills.

At the end of March 1996, there were 1569 textile mills in India, out of which 906 were spinning mills and 269 were composite mills with 28 million spindles and 1.6 lakh looms. This industry is provided direct employment to nearly 17.0 lakh workers which account nearly 18 per cent of the total factory workers of the country.

Again, total employment in textile sector is estimated about 35.00 million in 2002-03 as against 39 millions in 1990. There were 132 closed mills at the end of March, 1994.

ADVERTISEMENTS:

The textile industry has mainly three divisions:

(i) The highly mechanised mill industry producing yarn and cloth,

(ii) The power loom factories producing cloth from mill-made yarn and

(iii) The widely scattered handloom units producing cloth from both mill-made and hand spun yarn. Thus, the structure of the industry is very complex.

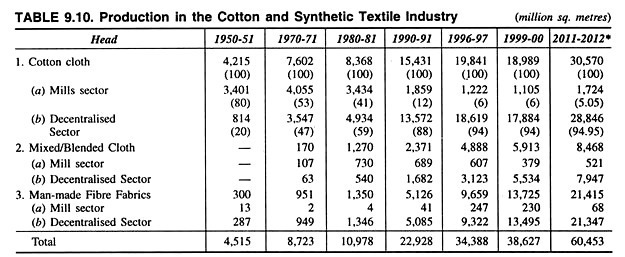

The present policy regime will result in more rapid and harmonious growth of the three regiments (mill, power loom and handloom) and also give a thrust to exports. Table 9.10 reveals the production of textile both in the mill sector and the decentralised sector.

Table 9.10 shows that the total production of cotton cloth increased from 4,215 million sq metres to 7,602 million sq. metres in 1970-71 and 15,431 million sq metres in 1990-91 and then increased to 30,570 million sq metres in 2011-2012.

One more peculiarity that can be seen here is that the share of decentralised sector has increased continuously from 20 per cent in 1950-51 to 47 per cent in 1970-71 and then to 94.95 per cent in 2011-12. Product of mixed or blended cloth also increased from 170 million sq metres in 1970- 71 to 2371 million sq. metres in 1990-91 and then again increased to 8,468 million sq metres in 2011-2012.

Again the production of man-made fibre fabrics also increased from 300 million sq metres in 1950-51 to 951 million sq metres in 1970-71 and then to 21,415 million sq metres in 2011-12. In case of the production of both of these mixed cloth and manmade fibres, the share of decentralised sector has increased considerably and constitutes the major portion of the output.

ADVERTISEMENTS:

The cotton arid synthetic industry is occupying a very unique place in the world export market. In respect of total quantity of export India’s position is second after Japan and catering to the needs of more than 16 per cent of world exports. Textile exports accounted for about 8.23 per cent of India’s total exports in 2008- 09.

It is also the largest net foreign exchange earner as the import content in textile goods is very low. During 2011-12 textile exports amounted to Rs 87,237 crore, which shows an increase of 32.1 per cent over the previous years.

Problems of Cotton Textile Industry in India:

The cotton textile industry in India has been suffering from the problems like:

(a) Obsolete machineries,

ADVERTISEMENTS:

(b) Problems of modernisation,

(c) Lack of raw materials,

(d) Non-utilisation of production capacities,

(e) Lack of power supply,

ADVERTISEMENTS:

(f) Increasing Government control and heavy excise duties,

(g) Higher unit cost of production,

(h) Inefficient and uneconomic units of production,

(i) Increasing labour problems,

(j) Increasing competition in foreign market,

(k) Shortage of finance and

ADVERTISEMENTS:

(l) Growing sickness among the textile industrial units.

Obviously, these have resulted in closure of 121 mills as on March 1988.

Again, during the period between 1995-96 to 2005-06, 379 private and non SSI textile mills were closed. As a result about 2.11 lakh workers were affected with the closure of 379 silk textile mills during the past decade. Moreover, Tamil Nadu has seen the largest number of 106 mills being closed, followed by 48 mills in Maharashtra, 46 mills in Gujarat and 31 mills in Andhra Pradesh.

Remedial Measures for Solving the Problem of Cotton Textile Industry:

In the meantime Government of India has taken certain positive steps for the improvement of conditions of cotton textile industry in India.

These steps are:

(a) Increasing financial assistance for its modernisation,

ADVERTISEMENTS:

(b) Reduction of import duties on the import of textile machineries,

(c) Reduction of excise duties on improved yarn,

(d) Setting up National Textile Corporation (NTC) to run the sick units,

(e) Introduction of new Textile Policy in 1985 for the modernisation and expansion of this industry.

In recent years,’ several policy measures have been adopted to improve the health of cotton textile industry.

These measures are as follows:

ADVERTISEMENTS:

1. Textile Modernisation Fund, set up in 1986 with a corpus of Rs 750 crore, has received an overwhelming response from the mills. Till the end of September 1992 financial institutions had sanctioned loans amounting to Rs 1,368 crore for 357 cases while disbursements aggregated to Rs 858 crore.

2. A turnaround strategy for the sick mills of NTC and BIC has been evolved by the Government. The package includes providing working capital finance to tide over the liquidity problems, capacity modernisation and shedding of surplus labour through a voluntary retirement scheme which will be handled through the recently established National Renewal Fund (NRF).

3. Other programmes relate to technological upgradation of the handloom sector, Power loom cooperative societies are being encouraged to upgrade capacities in this sector. It is expected that these policy measures will further encourage upgradation of capacities and a higher export orientation to the industry.

4. In line with the general policy of liberalisation, several measures have been undertaken to eliminate or reduce controls and bring about greater transparency in the textile sector. The textile industry has been de-licensed as per the Textiles (Development and Regulation) Order 1993.

The current Export Entitlement Distribution Policy (known as Quota Policy) effective from January 1994 to December 1996 aims at making the system of quotas more transparent and simple and realising increased unit values from textile and garment quotas and encourages non-quota export of garments.

The Agreement on Textiles and Clothing included as part of the Final Act of GATT, provide for a dismantling of the discriminatory quota regime practiced under the Multi-Fibre Arrangement (MFA), within a definite time span of 10 years.

ADVERTISEMENTS:

In the wake of the coming into force of the Agreement on Textiles and Clothing (ATC), the Current Export Entitlement Distribution Policy (known as Quota Policy) effective from January 1994 to December 1996 bas been formulated to enable the industry to meet the challenges in the international market.

Quota Policy is made simple and more transparent and is expected to lead to greater export earning and to facilitate the modernisation of the industry.

Keeping in view of the requirement of Agreement on Textile and Clothing (ATC), a new Long Term Quota policy applicable for the three years period 1997-99 for export of textile and garments covered by the Quota system has been announced on October 16, 1996. This new policy not only simplifies procedure and ensures greater transparency, but encourages higher value unit realisation for quota items.

In the meantime, the Government has finalised a plan to modernize sick textile mills in the private sector.

Accordingly two bills providing for Acquisition and Transfer of Textile Undertakings and amending the Sick Textile Undertakings (Nationalisation) Act were prepared and tabled in the Parliament in August, 1995 for the modernisation of 123 sick textile mills belonging to the National Textile Corporation without any financial assistance from the Government.

This modernisation programme is expected to be completed within one-and-a-half year and the finance for this modernisation would be provided from the sale of surplus land of these mills. Such modernisation would help in boosting the textile exports of the country under the present international trade regime under WTO.

In the face of progressive globalization, the textile industry requires improvement in product quality and cost efficiency. To meet this requirement, the Government has proposed two major initiatives, viz., Cotton Technology Mission (CTM) and Technology Upgradation Fund (TUF).

While the main thrust of CTM will be on improving productivity and quality of cotton, the TUF will address the problem of technology obsolescence particularly in the weaving and processing sectors of the industry.

These initiatives, when operationalized are expected to enhance cost efficiency and improve quality of production in textile industry. In July 1998, the Government also set up an Expert Group to review the existing textile policy and recommend changes against the emerging imperatives of international competition.

Thus, the two flagship schemes of the Ministry of Textiles, namely, the Technology Upgradation Fund Scheme (TUFS) launched in 1999, and the Scheme for Integrated Textile Parks (SITP) launched in 2005, have been approved for continuation in the Eleventh Five Year Plan. Under TUFS, loans worth Rs 27,449 crore were disbursed to 10,216 applicants’ up to March 2007.

Under SITP, 30 integrated textile parks of international standards, covering weaving, knitting, processing and garmenting sectors with project proposals worth Rs 2,893.42 crore (of which assistance from the Government is Rs1,054.76 crore) have been sanctioned. These projects are likely to be completed by March 2008.

Moreover, India’s textile sector is expected to attract investment of Rs 1, 50,600 crore during the Eleventh plan period and will achieve export target of Rs 2,25,665 crore (55 billion dollar) by 2012.

Despite the adverse impact of global recession in major export markets in US and European Union (EU), the textile industry could achieve turnaround from growth in cotton yarn production and 5 per cent growth in fabric production.

The Twelfth Plan has provided further impetus to the textile sector with a plan allocation of Rs 25,931 aimed at achieving 15 per cent export growth in value terms and 10 per cent growth in cloth production in volume terms.

Under the Integrated Skill Development Scheme introduced in 2010-11, around 70,000 persons have successfully completed training during 2012-13 and a total of 1,00,000 persons have been trained so far and Rs 1900 crore has been provided for training 15 lakh persons during the Twelfth Plan.

Under the restructured Technology Upgradation Fund Scheme (TUFS) Rs2, 151 crore was released as subsidy during 2012-13, the scheme will be continued in the Twelfth Plan with an outlay of Rs 11,952.80 crore.

Under the scheme of Integrated Textile Parks, commercial production has commenced in 26 out of 40 sanctioned Textile Parks giving employment to 44,000 persons. During the year 2012-13, cloth production increased by 5.0 per cent.

Besides, recognizing the relevance and potential of the technical textiles sector, a Rs 500 crore pilot scheme for promotion of technical textiles in the North East Region (NER) has been introduced.

Moreover, in order to address the special needs of the NER an outlay of Rs 1038.0 crore has been provided in the 12th plan for introducing new umbrella scheme enabling a project based approach with sufficient inbuilt flexibility for development of the textile sector in this region.